On June 20, 2019, Orange Wang, He Huffing and Sidney Leng write on South China Morning Post, Part Five:

- Mentions of ‘Made in China 2025’ may have disappeared, but Beijing and local governments continue to subsidise emerging technologies, sparking US outrage

- US President Donald Trump has long complained about China’s state subsidies, even accusing Chinese trade practises of ‘raping’ the American economy

Prospects of China and the US securing a deal to end the trade war are dwindling. This is the fifth in a series of long reads examining the elements of any deal that Beijing would be willing to agree to, those that are considered achievable in the long run, as well as the red lines, on which Beijing is unlikely to ever budge. Part five focuses on the complex issue of state subsidies for China’s hi-tech industries.

If Beijing’s phasing out of references to “Made in China 2025”, the ambitious blueprint for the country’s industrial upgrade, was supposed to convince the United States that it had dropped the plan, then an outburst from US President Donald Trump last week showed that the move had clearly failed.

In an interview with CNBC, Trump railed against the plan, claiming that he had told his Chinese counterpart Xi Jinping that it was “insulting” to America, and that it was his own threat of retaliation that led to the brand being quietly dropped.

Washington has long complained about China’s state subsidies. Trump has often directed his fury at heavy industry, railing against cheap Chinese steel flooding US markets, even accusing Chinese trade practises of “raping” the American economy. However, it is arguably Beijing’s subsidies for hi-tech industries that the US fears most, as can be showed by its pursuit of China’s technology giants, Huawei and ZTE.

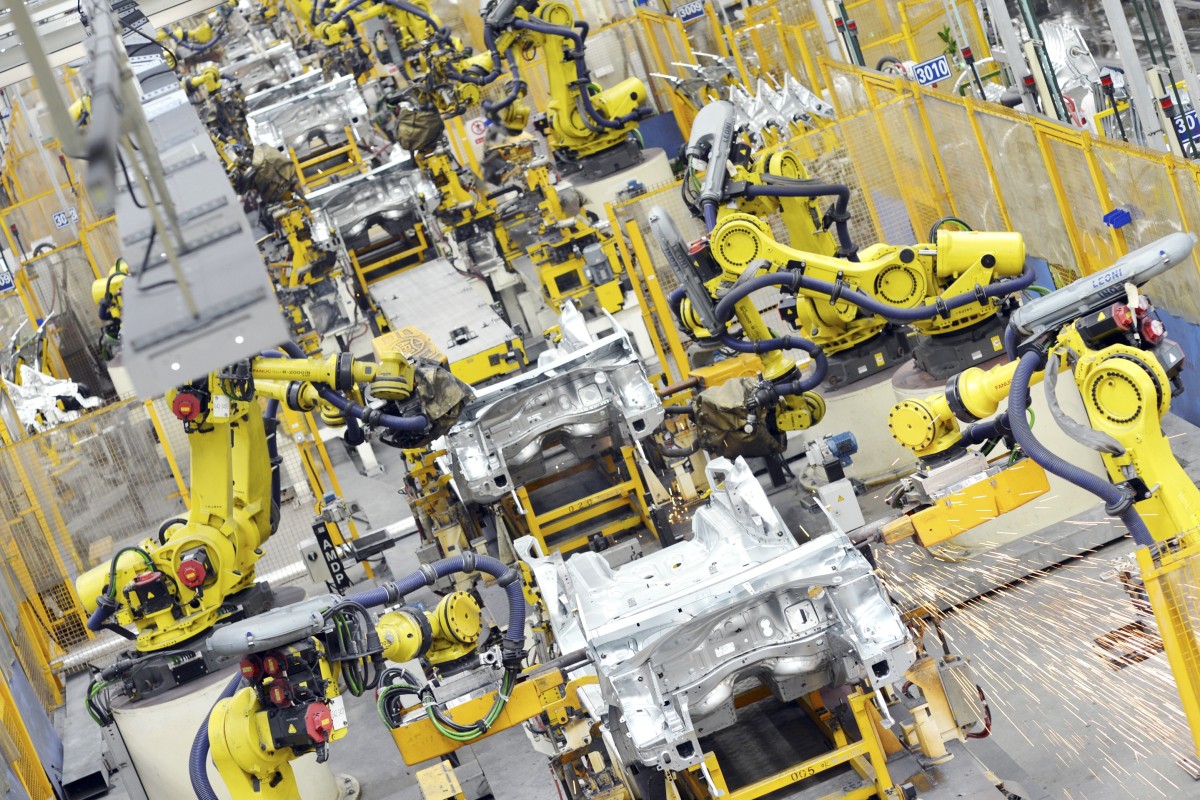

Both China and the US are aware that whoever dominates in technologies such as 5G, robotics, electric vehicles and cloud computing, could gain the upper hand in both trade and military terms in the decades ahead. Furthermore, the US government can look at industries such as electric vehicles and solar cells for precedents as to how China subsidises a developing technology to the point of dominance and only then winds down government support.

In the EV sector, China is beginning to reduce subsidies, but only at a stage when it is by far the global leader. In 2017, the country produced more electric vehicles than the rest of the world combined, 579,000, compared to 200,000 in the US and 98,000 in Japan.

China views these technologies as crucial to moving its manufacturing economy up the value chain and avoiding the dreaded middle income trap, where wages stagnate, igniting the potential for domestic unrest. In that regard, subsidising new industrial sectors – as with the state support continually pumped into job-rich industries like machinery and car manufacturing – helps keep discontent among the public muted.

For these reasons, hi-tech subsidies are viewed by many as a red line for China in the talks with the US to end the trade war. Conversations with industry insiders – many of whom receive subsidies – reveal little desire to change a model which suits them well.

Some even think that even with the billions being pumped into the sector from government coffers, Beijing is not doing enough, even though last year China was the world’s largest producer of industrial robots – the machines that automate production lines – for the sixth successive year, with 147,682 units made, according to date from OFweek.

Sun Kai, the chief technology officer of Beijing Elite Technology, a privately-owned industrial robot maker which opened a production plant in the manufacturing hub of Suzhou near Shanghai last year, said that he “absolutely” wanted the Chinese government to grant more financial support to the industry, despite US demands to stop.

“[The subsidies for buying robots] make little sense in terms of boosting the R&D on industrial robot technologies,” Sun said.

This year, the picture has been less rosy, with tariffs and a slowdown in global demand forcing industrial robot production down by 10.2 per cent in the first four months, according to OFWeek, a data resource for China’s hi-tech industries.

But that does not mean that Beijing has stopped subsidies. Government handouts accounted for 44 per cent of net profits for 53 listed robotic companies in 2018, according to a research note by Sinolink Securities, a sharp rise from the 10 per cent recorded between 2012 and 2017.

Robotic industry subsidies come in different forms, but they are delivered by government authorities across China. In 2014 and 2015 alone, more than 36 Chinese cities launched a total of 77 supportive policies for the sector, according to the China Robot Industry Alliance.

This led to an influx of companies to the sector, including private start-ups like Beijing Elite Technology and major, established manufacturing players, such as Gree, a state-owned home appliance maker based in Zhuhai, which created a subsidiary in September 2015 to produce industrial robots.

“Big powers in manufacturing are all ratcheting up the development of intelligent manufacturing. China also released the action plan for Made in China 2025. Within this context, Gree dug into the research and development of intelligent equipment,” said an unnamed Gree Intelligent Equipment executive in a statement received from the company, who declined to disclose how much the company had received in subsidies.

In Suzhou, the municipal government released a two-year funding plan in 2016 for smart devices and the internet of things, whereby 500 million yuan (US$72 million) would go towards helping manufacturers upgrade their production lines with one-time rewards of between 5 million yuan (US$722,000) and 10 million yuan.

These enable companies to purchase robots from companies such as Beijing Elite Technology, but Sun said that he would prefer the government channel funds directly into research and development (R&D).

“It makes little sense not to boost the R&D on industrial robot technologies,” Sun said, adding that 10 per cent of his companies budget came from government subsidies.

“China’s robot industry is still falling behind the ones in Europe, the United States, Japan and South Korea. Most [robot] companies that target the high-end market are facing huge financial pressure, mainly from the spending on research and development.”

Zhu Sendi, a member of the National Manufacturing Strategy Advisory Committee, told the Made in China Forum in Foshan earlier this year that while China is the world’s biggest manufacturer, building better industrial robots would help it catch up with the US in terms of efficiency.

“It is urgent now for China to consider the strategy of how to transform manufacturing from big to strong. Intelligent manufacturing should be the main direction,” he said.

This is a widely-held view within the sector and one backed up by research as a study by the Chinese Academy of Engineering showed that Chinese manufacturing is 15.48 per cent less efficient than its American equivalent, up from 11.68 per cent in 2012.

Chen Hongbo, the vice-president of Jaten Robot & Automation, a robot manufacturer in Foshan in China’s Guangdong province, said that “global economic and trade trends are not conducive” to innovation in China’s hi-tech sectors, with the drag on international demand caused by the trade war making it difficult for his company to invest in R&D.

“Tech enterprises, the government and talent should support each other to tide over the difficulties to improve the productivity of robot and intelligent manufacturing and promote the transformation of robotics companies,” Chen said, adding that government subsidies could help achieve this.

“Tech enterprises, the government and talent should support each other to tide over the difficulties to improve the productivity of robot and intelligent manufacturing and promote the transformation of robotics companies”

A separate Guangdong manufacturer based in Dongguan, who wished to remain anonymous, admitted that government subsidies form “about 30 per cent” of its R&D budget, which itself was up to 20 per cent of the company’s revenue.

“Government subsidies and incentives are an important boost to R&D, especially in the current economic downturn and uncertainties, which mean most Chinese companies have become more conservative with regard R&D investment than in previous years,” said the executive, whose company makes radio frequency identification equipment for controlling industrial robots.

The message from the robotics sector is clear: China should continue subsidising companies until the money is no longer needed, the technology is sufficiently developed and the companies able to sustain market forces.

“The US government thinks the monopoly of Chinese state-owned enterprises has been strengthening, so it is disgusted with China’s government subsidies. But even in mature market economies, the US or European Union, they also have government subsidies and financial support programmes in cutting-edge technology development,” said Luo Jun, chief executive of the International Robotics and Intelligent Equipment Industry Alliance, a government think tank.

Understandably, this is a point of frustration in Washington. Jeff Moon, assistant US trade representative for China during the final year of the Obama administration, cites the example of solar panels, which China subsidised to the point of domination, as well as Beijing’s plans last year to establish a 300 billion yuan (US$43.38 billion) fund to support its domestic semiconductor industry.

“I don’t think that [the Trump administration] think they are going to wipe out all subsidies, but I think that putting some really outrageous number against semiconductors, then that is completely changing the entire industry,” Moon said.

“If China is claiming that it has the right to now subsidise beyond anyone’s wildest expectations a company that is going to sell products below market prices, engage in predatory pricing, bankrupt companies all around the world, and that is how they are going to achieve Made in China 2025, by first capturing the Chinese market and then capturing world markets, well, then there’s a reason to have a trade war and we ought to fight it.”

In China’s electric vehicle sector, where subsidies are being reduced, companies are racing against time to innovate before they are fully exposed to market forces. Beijing’s latest policy plan showed that this year, subsidies for all electric vehicles combined would be half last year’s level and are expected to be completely phased out by the end of next year.

The plan also forbids local governments from subsidising electric passenger vehicles starting from this month – subsidies for electric public transports and fuel cells are still allowed – but encourages local officials to fund more infrastructure construction, such as charging stations.

Chongqing Sokon Industry Group, a private Chongqing-based company, mainly produces low-end electric vehicles that are reliant on subsidies. According its annual report, nearly 40 per cent of its electric vehicle revenue came from government subsidies last year.

“The subsidy is only a guidance. The government eventually will let the market play a bigger role. The subsidy can only raise a lot of locusts. Any subsidy policy is not a long-term solution,” said an analyst at the company, who preferred not to be named.

Sokon has been pouring funds – 10 billion yuan (US$1.4 billion) over five years – into an advanced new model, its plug-in hybrid electric vehicle, with its self-developed engine, with a view to mass-producing later this year. The company is betting on the new model to boost revenues that have been hit by China’s sluggish vehicle market and help reduce some of its debt burden, which has risen to more than 70 per cent of its assets.

It is easy to see why China is now happy to stop propping up its electric vehicle industry as it is already miles ahead of other competing nations. Bloomberg reported earlier in June that there are already 486 electric vehicle start-ups in China, many of which are yet to introduce their first commercial products. Despite this, there were more than 1 million electric vehicle sales in China for the first time in 2018.

Other tech-related issues in the trade war, such as an end to intellectual property violations and forced technology transfer, are viewed as items China can accept and address in the medium-term. However, as it strives to be the global power in new technologies, Beijing appears less inclined to meet US demands on subsidies.